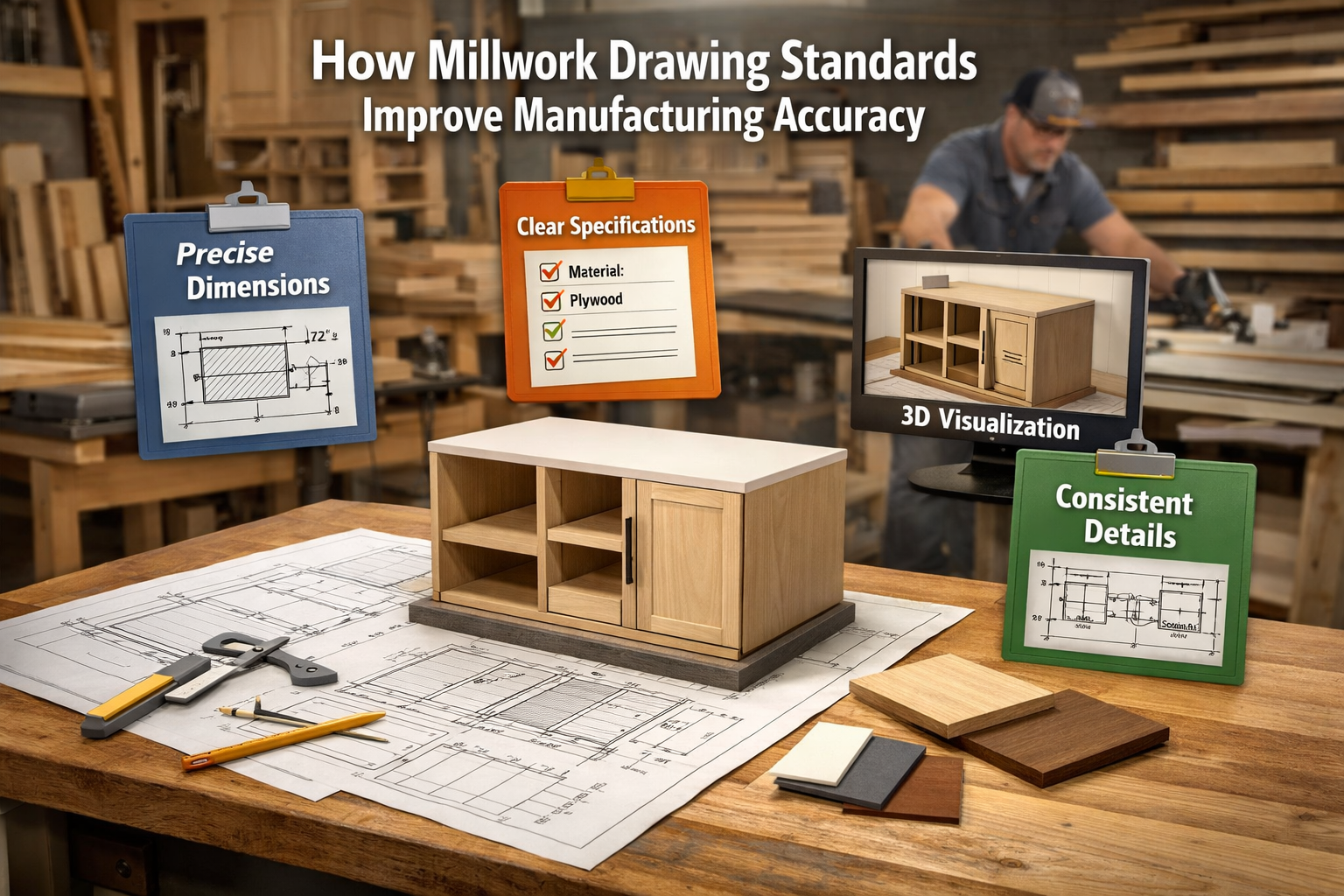

In today’s highly competitive construction and manufacturing environment, accuracy is no longer optional, it’s essential. From custom cabinetry and architectural woodwork to complex interior fit-outs, millwork drawing standards play a pivotal role in ensuring that what’s designed is exactly what gets manufactured and installed.

With increasing demand for precision, shorter project timelines, and tighter budgets especially across the USA and UK manufacturers, architects, and contractors are relying heavily on standardized millwork CAD documentation to avoid costly errors. According to industry reports by McKinsey, construction rework caused by design inaccuracies can account for up to 30% of total project costs, highlighting how critical accurate drawings have become.

So how exactly do standardized millwork drawings improve manufacturing accuracy? And why should decision-makers pay close attention to them in 2025 and beyond?

Let’s break it down.

What Are Millwork Drawing Standards?

Millwork drawing standards refer to a set of established guidelines and best practices used to create consistent, precise, and readable millwork detail drawings and millwork CAD drawings.

These standards typically define:

- Dimensioning methods

- Material callouts

- Joinery details

- Tolerances

- Section views and elevations

- Hardware specifications

- Notes and annotations

Organizations such as the Architectural Woodwork Institute (AWI) and British Standards Institution (BSI) provide recognized frameworks that manufacturers and designers across the USA and UK commonly follow.

By adhering to these standards, every stakeholder from designers to CNC machine operators interprets the drawings the same way.

How Do Millwork Drawing Standards Reduce Manufacturing Errors?

One of the biggest advantages of standardized millwork drawings is error reduction.

Why Do Errors Happen Without Standards?

Without consistent standards, manufacturers often face:

- Ambiguous dimensions

- Missing tolerances

- Unclear material specifications

- Conflicting elevations and sections

According to data from Autodesk Construction Cloud, poor-quality construction documentation is one of the top causes of rework in manufacturing-driven projects.

How Standards Solve This Problem

Millwork drawing standards eliminate guesswork by ensuring:

- Every dimension is clearly defined

- Joinery and assembly methods are visually explained

- CNC-ready information is included

- Material thicknesses and finishes are standardized

This clarity leads directly to fewer shop-floor mistakes and higher manufacturing accuracy.

Why Are Millwork Detail Drawings Essential for CNC Manufacturing?

As CNC machining becomes the norm across the USA and UK, the quality of millwork detail drawings has a direct impact on production efficiency.

What CNC Machines Require

CNC equipment relies on:

- Precise dimensions

- Accurate tool paths

- Consistent tolerances

- Standardized layer naming and annotations

Even a small deviation in drawings can result in:

- Material waste

- Machine downtime

- Incorrect cuts

By following millwork drawing standards, CAD teams ensure that drawings translate seamlessly into machine-readable formats.

How Do Standardized Millwork CAD Drawings Improve Cross-Team Collaboration?

Modern construction projects involve multiple stakeholders often spread across countries and time zones.

Why Collaboration Breaks Down

Miscommunication often occurs when:

- Designers use different drafting conventions

- Manufacturers interpret drawings differently

- Installers receive unclear assembly instructions

A survey by Deloitte found that over 60% of manufacturing delays are linked to communication and documentation issues.

The Role of Standardization

Standardized millwork CAD drawings act as a universal language by:

- Creating consistent symbols and notation

- Aligning expectations across teams

- Reducing back-and-forth clarifications

This is especially valuable for global projects involving USA-based architects and UK-based fabrication teams.

What Are the Latest Trends Influencing Millwork Drawing Standards?

The CAD design and drafting industry is evolving rapidly. Several trends are reshaping how millwork drawings are created and used.

1. Increased Use of BIM Integration

Millwork drawings are no longer isolated 2D documents. They’re increasingly integrated into BIM workflows.

Benefits include:

- Clash detection with MEP systems

- Accurate quantity take-offs

- Improved coordination

According to Statista, BIM adoption in North America has surpassed 70%, pushing millwork drawings toward higher precision standards.

- Shift Toward Prefabrication and Modular Construction

Prefabricated millwork components require near-zero tolerance errors.

Standardized drawings support:

- Factory-based assembly

- Faster on-site installation

- Reduced labor costs

This trend is especially strong in the UK, where modular construction is growing at over 6% annually, as reported by Construction Products Association (CPA).

- Demand for Sustainability and Material Efficiency

Sustainable manufacturing relies on minimizing waste.

Accurate millwork detail drawings help by:

- Optimizing material usage

- Reducing offcuts

- Supporting eco-certified wood sourcing

Green building certifications increasingly require precise documentation to validate sustainability claims.

How Do Millwork Drawing Standards Impact Project Timelines?

Time overruns are one of the most common pain points in construction and manufacturing projects.

The Cost of Delays

The Construction Industry Institute reports that schedule overruns can inflate project costs by 10–20%.

How Standards Speed Things Up

Standardized millwork drawing services contribute to faster timelines by:

- Reducing RFIs (Requests for Information)

- Accelerating approvals

- Streamlining fabrication workflows

- Minimizing revisions

Clear, standardized drawings move smoothly from design approval to production without unnecessary friction.

Are Millwork Drawing Standards Important for Compliance and Quality Control?

Absolutely.

Meeting Industry and Client Expectations

Many commercial and institutional projects require compliance with:

- AWI Quality Standards (USA)

- British Standards (UK)

- ISO documentation protocols

Non-compliant drawings can lead to rejected shop drawings or failed inspections.

Improving Quality Assurance

Standardized drawings support:

- Easier quality checks

- Consistent production output

- Better traceability during audits

This is especially important for high-end architectural millwork, hospitality projects, and healthcare interiors.

What Challenges Do Companies Face When Implementing Drawing Standards?

Despite the benefits, adopting standardized millwork drawing practices isn’t without challenges.

Common Obstacles Include:

- Legacy drafting habits

- Inconsistent CAD training

- Lack of updated standards knowledge

- Pressure to deliver drawings quickly

However, companies that invest in skilled millwork drawing services and standardized workflows often see long-term cost savings that far outweigh initial setup efforts.

How Can Businesses Leverage Millwork Drawing Standards for Competitive Advantage?

For business owners and decision-makers, standardized drawings are more than a technical requirement; they’re a strategic advantage.

Key Business Benefits

- Higher manufacturing accuracy

- Reduced rework costs

- Faster project delivery

- Stronger client trust

- Scalability across global markets

In a competitive CAD outsourcing landscape, companies that deliver consistent, standards-driven documentation stand out.

Final Thoughts:

As construction and manufacturing become increasingly data-driven, the role of millwork drawing standards continues to expand. They bridge the gap between design intent and manufacturing reality ensuring accuracy, efficiency, and quality at every stage.

For architects, engineers, manufacturers, and startups operating in the USA and UK, investing in standardized millwork documentation isn’t just about avoiding mistakes, it’s about building smarter, faster, and more sustainably.

In today’s global CAD ecosystem, partnering with an experienced UK-based CAD design company that understands international millwork standards can help businesses stay ahead without compromising accuracy or timelines.